Looking for the best mitre saw blade for composite decking? Look no further! Our comprehensive guide will help you find the perfect blade to make clean and precise cuts on your composite decking material. Whether you’re a professional contractor or a DIY enthusiast, we’ve got you covered. Read on to discover our top recommendations and upgrade your cutting game today!

How We Tested?

Why is the Best Mitre Saw Blade for Composite Decking Necessary?

Composite decking has gained immense popularity due to its durability, low maintenance requirements, and aesthetic appeal. It is a fantastic alternative to traditional wood decking as it is resistant to decay, fading, and warping. However, working with composite decking materials requires specialized tools, including the best mitre saw blade.

1. Clean and Precise Cuts

When cutting composite decking boards for installation or customization, using the right blade is crucial for achieving clean and precise cuts. The best mitre saw blade for composite decking is specifically designed to handle the unique composition of these materials without causing splintering or chipping.

2. Reduced Risk of Damage

With standard blades or incorrect tools, there is a higher risk of damaging the composite decking boards while cutting. This can lead to compromised structural integrity and an unappealing finish. By investing in the best mitre saw blade designed for composite decking, you minimize this risk significantly.

3. Increased Efficiency

Using a high-quality mitre saw blade ensures smooth and efficient cutting through composite decking materials. It reduces friction and prevents excessive heat buildup during the cutting process, allowing you to complete your projects faster and with greater ease.

4. Longevity of Composite Decking

Choosing the correct blade helps maintain the longevity of your composite deck by ensuring that each cut is precise and clean. Poorly cut edges can create weak points where moisture can penetrate, leading to potential damage over time. By using the best mitre saw blade for composite decking, you minimize this risk while preserving the overall quality and lifespan of your deck.

5. Cost-effective Solution

While investing in a specialized blade may seem like an additional expense upfront, it proves to be cost-effective in the long run. By using a high-quality mitre saw blade specifically designed for composite materials, you avoid costly mistakes, material wastage, and the need for additional repairs or replacements.

Conclusion

In conclusion, using the best mitre saw blade for composite decking is necessary to ensure clean and precise cuts, reduce the risk of damage, increase efficiency, maintain the longevity of your deck, and provide a cost-effective solution. By choosing the correct tool for the job, you can achieve professional-grade results while working with composite decking materials.

Our Top Picks

1. Freud D0744CD Trex Composite Decking Circular Saw Blade Ideal

Experience effortless cutting with the Freud D0744CD Circular Saw Blade. Its multi-colored design not only looks great, but its sharp teeth ensure clean and precise cuts on composite decking and other materials. Upgrade your circular saw blade today and enjoy professional results.

Product Features:

- 7-1/4-inch diameter

- 5/8-inch arbor

- 44 Modified Triple Chip Grind-MTCG Teeth

- Laser cut stabilizer vents keep the blade straight and true for superior quality cuts and no swirl marks

- Multi-colored design adds visual appeal

- Sharp teeth for clean and precise cuts

- Versatile blade suitable for various materials

- May require frequent sharpening with heavy use

- Limited compatibility with certain circular saw models

- Slightly heavier compared to other blades

| Product Info | |

|---|---|

| Brand | Freud |

| Manufacturer | Freud |

| Color | Multi |

| Item Dimensions | (Height: 0.51 Inches, Length: 6.25 Inches, Weight: 0.15 pounds, Width: 0.82 Inches) |

| Size | One Size |

2. DEWALT Circular Saw Blade, 7 1/4 Inch, 40 Tooth, Composite Decking (DWA31740)

Achieve smooth and accurate cuts on your composite decking with the DEWALT DWA31740 Circular Saw Blade. Its 40-tooth design ensures efficient cutting performance, while the high-quality construction guarantees durability even under heavy use. Upgrade your circular saw blade today.

Product Features:

- Features a modified triple chip grind tooth design

- Designed for composite decking

- Laser-cut plate design for cool, metal-free cuts

- 7-1/4″ Diameter, 5/8″ Arbor

- Efficient 40-tooth design for fast cutting

- High-quality construction for long-lasting performance

- Suitable for cutting composite decking

- Limited tooth count compared to other options

- May not fit all circular saw models

- Compatibility with materials other than composite decking may be limited

| Product Info | |

|---|---|

| Brand | DEWALT |

| Manufacturer | DEWALT |

| Item Dimensions | (Height: 8.75 Inches, Length: 0.5 Inches, Width: 9.75 Inches) |

| Size | 7-1/4″ |

3. Norske Tools NCSBP226 7-1/4 inch x 48T Composite Decking (Trex) and Bamboo Decking Saw Blade

Get precise and clean cuts on your composite and bamboo decking with the Norske Tools NCSBP226 Saw Blade. Its diamond knockout Japanese steel construction ensures durability, while the 48-tooth design guarantees smooth cutting performance. Upgrade your toolset today.

Product Features:

- 7-1/4 inch x 48 teeth

- Specially designed to maximize cutting life in composite decking materials and cellular PVC

- Modified triple chip grind (MTCG) tooth profile for clean, cool and “melt free” cutting

- Ultra-thin kerf design provides fast and clean cuts with minimal material removal

- Protection Non-Stick coating reduces drag and shields the blade against gumming, corrosion and heat

- Ideal for cutting bamboo decking

- Durable diamond knockout Japanese steel construction

- Sharp teeth for clean and precise cuts

- Suitable for cutting composite and bamboo decking

- Limited compatibility with materials other than composite and bamboo decking

- May require frequent sharpening with heavy use

- Slightly heavier compared to other blades

| Product Info | |

|---|---|

| Brand | Norske |

| Manufacturer | Norke Tools Ltd |

| Color | Black |

| Item Dimensions | (Height: 7.25 Inches, Length: 7.25 Inches, Weight: 0.5 pounds, Width: 0.13 Inches) |

| Size | 7-1/4″ |

4. Diablo by Freud Diablo DJT144DHM Carbide T-Shank Jig Saw Blade for Composite Decking

Enhance your jig saw’s performance with the Diablo DJT144DHM Jig Saw Blade. Its carbide-tipped teeth ensure efficient cutting on composite decking, while its multi-colored design adds a touch of style to your tools collection. Upgrade your jig saw blade today and enjoy professional results.

Product Features:

- Aggressive carbide tooth geometry delivers fast and effortless cuts

- Enhanced carbide tip to blade connection for extreme impact resistance

- T-shank design fits all combo and most U-shank jig saws

- Maximum performance in cordless and corded jig saws

- Carbide-tipped teeth for efficient cutting

- Multi-colored design adds visual appeal

- Suitable for cutting composite decking

- Limited compatibility with certain jig saw models

- May not fit all T-shank systems

- Requires careful handling to avoid damage to the blade

| Product Info | |

|---|---|

| Brand | Freud |

| Manufacturer | Freud |

| Color | Multi |

| Item Dimensions | (Height: 0.2 Inches, Length: 2.17 Inches, Width: 6.69 Inches) |

| Size | One Size |

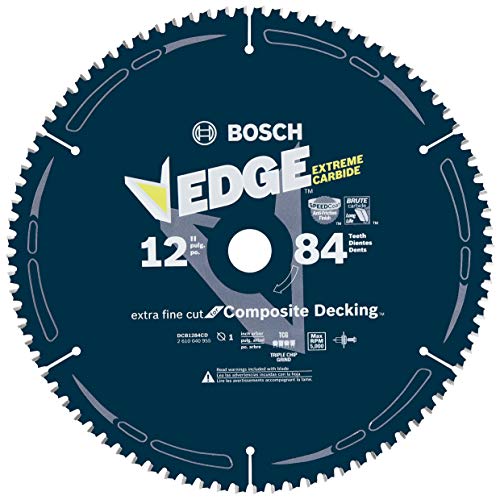

5. Crescent Circular Saw Blade 12 inches X 84 Tooth Composite Decking

Cut through composite decking with ease using the Crescent Circular Saw Blade. Its 84-tooth design ensures clean and precise cuts, while its high-quality construction guarantees long-lasting performance. Upgrade your circular saw blade today and experience professional results.

Product Features:

- Razor Tipped premium carbide teeth provide a 50% smoother finish

- Optimized tooth geometry for clean, melt-free cuts

- Cordless and corded performance for maximum versatility

- Active Shield blade coating protects against heat for reduced gumming

- Thin kerf design for fast, precise cuts

- High tooth count for clean cuts

- Durable construction for long-lasting performance

- Suitable for cutting composite decking

- Limited compatibility with materials other than composite decking

- May not fit all circular saw models

- Slightly heavier compared to other blades

| Product Info | |

|---|---|

| Brand | Crescent |

| Manufacturer | Apex Tool Group |

6. Concord Blades DEK0650T056SP 6-1/2″ 56 Tooth Composite Decking Non-stick Coated Blade

Experience smooth and efficient cutting on your composite decking with the Concord Blades DEK0650T056SP Circular Saw Blade. Its non-stick coated design ensures minimal friction, while its sharp teeth provide precise and clean cuts every time. Upgrade your circular saw blade today.

Product Features:

- Laser-cut Technology: The entire blade body is precision cut, never stamped out.

- Heat Expansion Slots: Specially designed to dissipate heat and keep the blade running cool.

- Anti-Friction Vents: Sound-dampening poly filler in every vent to help prevent vibration.

- Non-Stick TECNO Coating: Keeps the blade from gumming up and prevents burning.

- Composite Decking

- Non-stick coated design reduces friction

- Sharp teeth for clean and precise cuts

- Suitable for cutting composite decking

- Limited compatibility with materials other than composite decking

- May require frequent cleaning to maintain non-stick coating effectiveness

- Slightly smaller size compared to standard circular saw blades

| Product Info | |

|---|---|

| Brand | Concord Blades |

| Manufacturer | Concord Blades |

| Item Dimensions | (Height: 6.5 Inches, Length: 6.5 Inches, Width: 0.25 Inches) |

| Size | 6.5″ x 56T |

7. Luckyway 12 Inch Miter Saw Blade 80T with 1 Inch Arbor TCT Circular Saw Blade for Cutting Wood

Upgrade your miter saw blade with the Luckyway 12 Inch Miter Saw Blade. Its 80-tooth design ensures smooth cutting performance on wood, while its silver color adds a touch of elegance to your tools collection. Invest in quality and achieve precise cuts on your woodworking projects.

Product Features:

- DIMENSIONS – Includes 1pc 12*1*80T TCT circular saw blade.

- APPLICATION – Ideal for cross-cutting softwood, hardwood, plywood, chipboard, multi-board, panels, MDF,plated&counted-plated panels, laminated&Bi-laminate plastic, and FRP. Providing a high degree of finish edge. The blades also can rip cut along the grain.

- MATERIAL – Fully hardened steel blade body – delivers accuracy and resists bending and deflection for true cuts.

- FEATURES – Incorporates an ATB (Alternating Top Bevel) offset tooth design, The angle of the tooth scores the surface of the wood in advance of the cut, cleanly cutting the wood fibers before the following teeth remove the chip. This provides for a much smoother cut, with much less chance of splintering the surface of the wood.

- Tungsten carbide teeth provide excellent wear and heat resistance. The positive cutting angle which provides fast and efficient removal of chips and swarf.

- High tooth count for smooth cuts

- Suitable for cutting wood

- Silver color adds visual appeal

- Limited compatibility with materials

| Product Info | |

|---|---|

| Brand | Luckyway |

| Manufacturer | Zhenjiang Luckyway Tools Co.,Ltd |

| Color | Silver |

| Size | 12 Inch 80T |

Buying Guide: Choosing the Best Mitre Saw Blade for Composite Decking

Composite decking is a popular choice for outdoor spaces due to its durability, low maintenance, and aesthetic appeal. To achieve clean and precise cuts when working with composite decking materials, it is crucial to choose the right mitre saw blade. Here are some factors to consider when selecting the best mitre saw blade for composite decking:

Blade Type

There are different types of blades available for mitre saws, including rip blades, crosscut blades, combination blades, and specialized blades. When working with composite decking, it is recommended to use a crosscut or combination blade. These blade types have finer teeth which provide cleaner cuts on composite materials without causing excessive splintering.

Tooth Count

The number of teeth on a blade affects the smoothness and speed of the cut. For composite decking, a blade with a higher tooth count is generally preferred as it produces smoother finishes. Blades with 60 to 80 teeth are commonly used for cutting composite materials.

Blade Material

The material used in the construction of the blade impacts its performance and longevity. Carbide-tipped blades are widely regarded as an excellent choice for cutting composite decking due to their exceptional durability and resistance to wear. They can withstand the abrasive nature of these materials while maintaining sharpness over time.

Blade Size

Choosing the right size of the blade is essential for achieving accurate cuts. Most mitre saws are compatible with 10-inch or 12-inch blades. The size you need depends on the thickness and width of your composite decking boards. Ensure that your chosen saw blade has enough clearance to cut through your specific deck board dimensions.

Cutting Speed

Consider the cutting speed required for your project when selecting a mitre saw blade. Blades designed specifically for cutting composite materials often have special features that enhance cutting efficiency and reduce heat build-up during prolonged use.

User Reviews and Recommendations

Before making a purchase, it’s always a good idea to read user reviews and seek recommendations from professionals or experienced DIY enthusiasts. Their insights can provide valuable information about the performance, durability, and overall suitability of different mitre saw blades for composite decking projects.

Remember to prioritize safety while working with any power tools. Always follow the manufacturer’s instructions, wear appropriate safety gear, and take necessary precautions to protect yourself and others during the cutting process.

By considering these factors and following our buying guide, you can confidently choose the best mitre saw blade for your composite decking project without endorsing any specific product.

FAQs

What is the best mitre saw blade for composite decking?

The best mitre saw blade for composite decking is one that offers clean and precise cuts without causing any damage to the material. It should have specially designed teeth to handle the unique properties of composite decking, ensuring smooth and splinter-free cuts.

How can I choose the right mitre saw blade for cutting composite decking?

When selecting a mitre saw blade for cutting composite decking, look for blades specifically designed for this material. Consider factors such as tooth design, size, and durability. Opt for blades with carbide tips or diamond coating as they tend to deliver excellent results on composite materials.

Are there any specific features I should consider when buying a mitre saw blade for composite decking?

Yes, it’s important to consider certain features when purchasing a mitre saw blade for composite decking. Look for blades with anti-vibration technology to minimize noise and vibrations during operation. Additionally, blades with non-stick coatings can reduce friction and prevent the build-up of debris, ensuring smoother cuts.

Can using the wrong type of mitre saw blade damage my composite decking?

Yes, using the wrong type of mitre saw blade can potentially damage your composite decking. Blades that are not specifically designed for cutting this material may cause splintering, chipping, or even melting. It’s crucial to use a blade that is suitable for working with composites to ensure clean and accurate cuts without compromising the integrity of the material.

What are some recommended brands known for their high-quality mitre saw blades suitable for cutting composite decking?

Some reputable brands known for producing high-quality mitre saw blades suitable for cutting composite decking include Diablo, Freud, and CMT. These brands offer a range of options with specialized tooth configurations and durable construction to ensure optimal performance on composite materials.

How often should I replace my mitre saw blade when working with composite decking?

The frequency of blade replacement depends on several factors, such as the intensity of use and the quality of the blade. However, as a general rule, it’s recommended to replace your mitre saw blade for cutting composite decking after every 1000-1500 linear feet to maintain optimal cutting performance and avoid any potential damage to the material.